bg1

BIOcoal

From Biomass

renewable energy, biomass processing

is a company engaged in renewable energy, biomass processing technology by HTC metod to a greater caloric content. The company that supports the processing based on continuous processing of different types of biomass (dry or wet) in to biocoal that is CO² neutral. HTC technology Hydro-Thermal carbonization is represented as a way of processing.

The process is carried out similarly to the natural creation of the coal under controlled conditions, but this process is accelerated in to several hours. The process consists of reactor system (high pressure vessels) that under certain conditions (temperature 180 ° C - 220 ° C, high pressure) convert biomass into a different kind of uniform product - BIOUCOAL. Almost 100% of the carbon content in biomass is allocated into a commercial product.

How much carbon ends up as fuel?

HTC carbonation has one significant advantage over other methods of processing. The process is exothermic-releases energy during the transition from biomass in BIOUGALJ. Energy that is needed for the process is almost entirely covered by exothermic reactions. This makes the processing self-sustaining highly profitable.

Hydrothermal carbonization

HTC is a chemical process that transforms biomass in an anaerobic (without air) environment, under the temperature of 220 ° C and pressure (22 bar), to CO ² neutral- biocoal, which is similar to high quality lignite .Chemical process takes place in a vessel under pressure-reactor

Exothermic process allows that system does not require additional energy. Hydrothermal carbonization is characterized by the ability to process biomass with high water content.

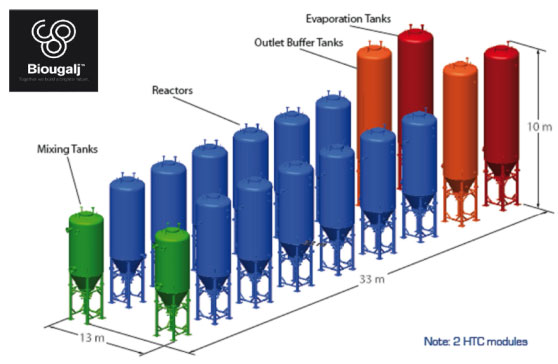

The plant consists of mixing tank, a series of courts-pressure reactor, in which a chemical process occurs, intermediate storage tank for the final product.

The plant has separate systems for different types of biomass (wet and dry). Pressure vessels are designed so that processing power can help and accelerate within the system. This system allows for minimal energy loss. Characterized not smell it, does not produce noise.

The plant consists of a mixing tank, a series of vessels- reactors under pressure in which a chemical process occurs, storage tank for the final product.